PROCESS

ISO 9001:2008 & ISO 22000:2005 Certified Company

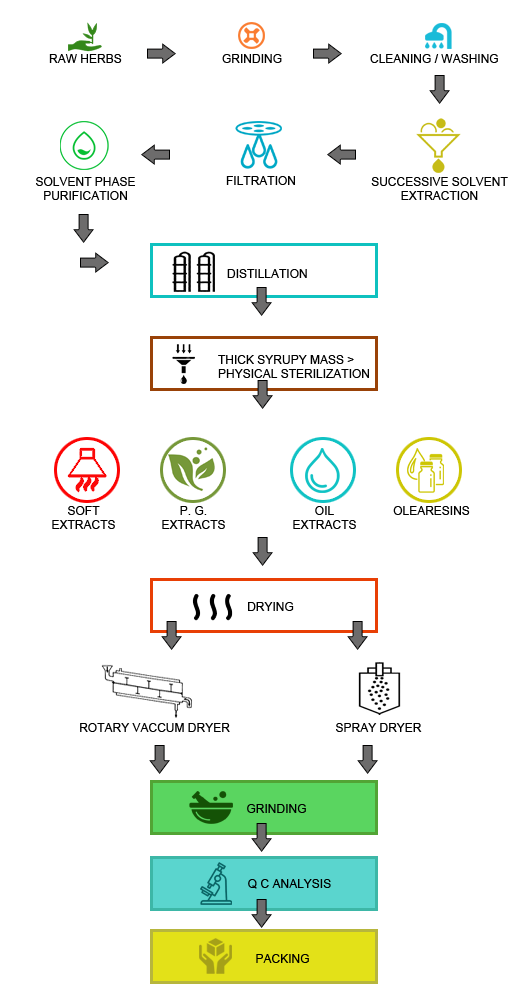

Extraction Process

Plant extraction is a process that aims to extract certain components present in plants. It is a solid/liquid separation operation: a solid object (the plant) is placed in contact with a fluid (the solvent). The plant components of interest are then solubilised and contained within the solvent. The solution thus obtained is the desired extract. The solvent will eventually be eliminated to isolate the plant extract. If it is for the food industry, it is not necessary to separate it from the extract. If not, a second separation operation makes it possible to obtain a dry extract. Nowadays, the term “extract” is frequently used incorrectly. In fact, only solid/liquid extraction is capable of producing them, but sometimes simple crushed plant powders are marketed as “extracts”.

The origin of the extraction of active plant ingredients has been lost to time. It was in fact very early on that mankind discovered the benefits of plants and the first techniques for separating out what we now refer to as “extracts”. The first extracts were essentially obtained through aqueous extraction or alcoholic fermentation, and according to procedures such as infusion, maceration, decoction and hydrodistillation. The simplicity of these procedures, as well as the tools, materials and heating methods of the time, meant that the extractor was a man of the arts rather than a scientist.

Today, this activity calls upon the use of precise automatons and adapted materials. It has benefited from advances in process engineering, phytochemistry and analytics. Moreover, new technologies to assist extraction (high-pressure, microwaves, ultrasound, etc.) are being developed. However, the notion of expertise in plant extraction remains to this day a balanced combination of the mastery of technical parameters, and tradition.